Additive

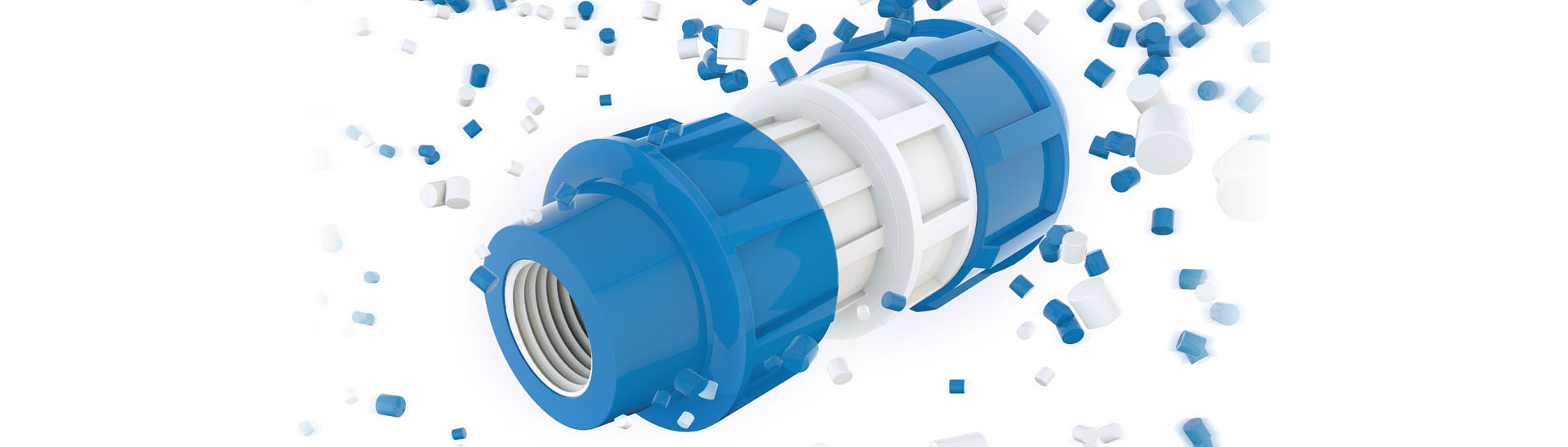

In addition to masterbatches, Biomasterbatches® and MasterbatchRecy®, we also offer our customers a 360° service for the transformation of plastic materials. Our additives supplement the basic molecular aspects when added to plastic during the production of a finished product. This operation creates a new product with specific technical characteristics. There are myriad different requirements involved when using an additive so the world of additives is vast and complex.

Our company has decided to make it our personal mission to offer the most comprehensive range of additives possible.

Firstly, our research focuses on certified basic active ingredients. Safety starts with analyses to identify reliable, high-performance active ingredients. Comparisons are then made using the analyses performed by our two in-house laboratories and results from the University Institutes with which we work.

Our years of experience provide the real confirmation and prove whether what has been experimented in the laboratory will work in practice.

We supply additives for all types of thermoplastic resins, each one with its own chemical properties.

THE PURPOSES

From working on the molecules of thermoplastic resin to improve workability, to developing solutions to boost transparency with a clarification technique that meets the requirements of the transformer. The use of our additives also plays an important role in ensuring that the finished product has properties that create added value so it stands out from others available on the market. For example, the traditional UV additives with the addition of anti-oxidant that provide resistance over time and also protect against the natural ageing of the plastic. Construction, automotive, outdoor technology, and aerospace parts are just some of the many fields of application.

Other specific industries demand attention to the aspects concerning the presence of water and sunshine, from farming to plastic film for outdoor use and packaging, and we have achieved major, long-lasting results in all these cases thanks to ad hoc desiccants and anti-fog products.

We look forward to illustrating all the infinite applications of our additives so we can meet the demands of your market with products that have been successfully tried and tested over time and guarantee proven reliability.

RANGE OF ADDITIVE MASTERBATCHES

MOTHPROOF

ANTISTATIC

PROCESSING AIDS

ANTI-FOG

ANTIBACTERIAL

ANTIBLOCKING

SCRATCHPROOF

FLAMEPROOF

ANTIFUNGAL

ANTIOXIDANT

ANTI-UV

ANTISTATIC

CLARIFIER

DESICCANT

DIFFUSING

NUCLEATING

LASER MARKER

OPACIFIERS

SOLAR REFLECTORS

SLIP